Food Processing

SANITARY PRECISION

Stainless systems engineered for 3-A, USDA, and FDA compliance.

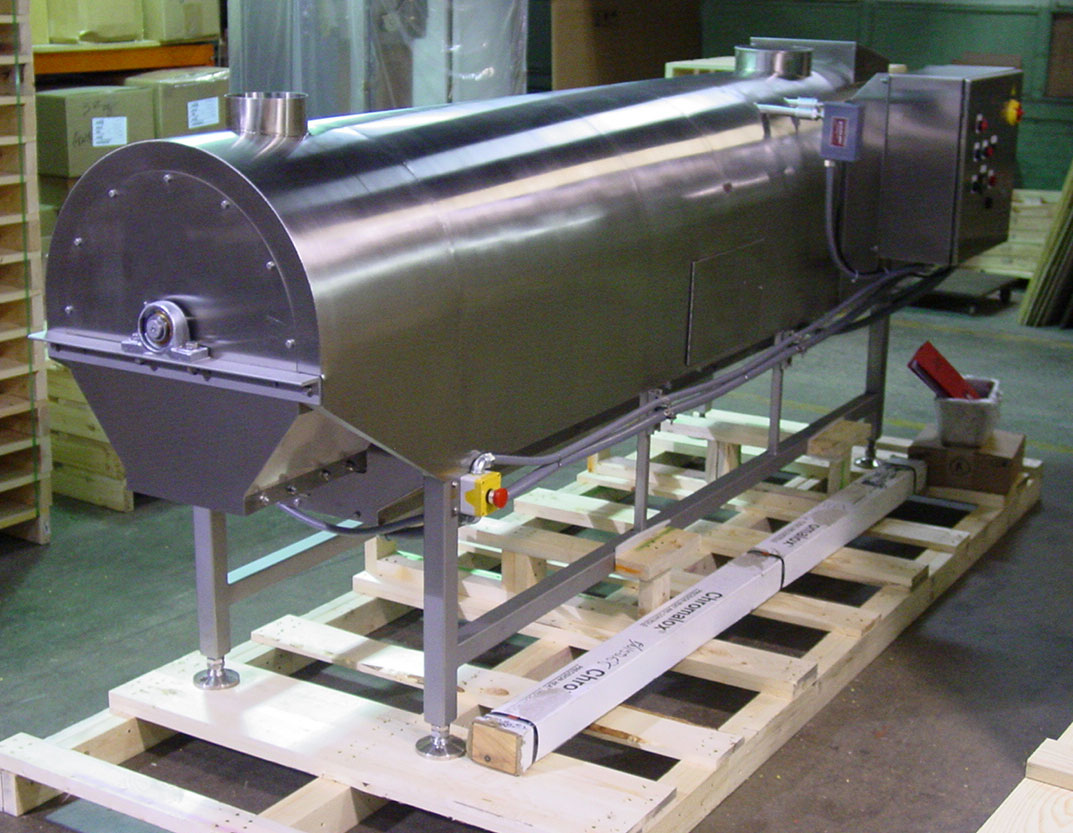

For more than six decades, ACE Metal Crafts Company has supported leading food-processing OEMs and system integrators with stainless components, sub-assemblies, and turnkey systems built for the highest sanitary performance. Our engineers and fabricators understand the relationship between weld quality, surface finish, and hygiene—ensuring every part meets 3-A Sanitary Standards, USDA criteria, and FDA expectations for cleanability and safety.

At ACE, sanitary fabrication is both science and craft. Our teams combine TIG and orbital welding, nitrogen purging, and finishing expertise that includes polished, bead-blasted, and electropolished surfaces from #4 satin to #8 mirror. Every auger, hopper, frame, and vessel is documented and traceable for full compliance, built to perform safely through CIP (clean-in-place) and SIP (steam-in-place) cycles.

Our customers trust us with their reputation. That’s why precision isn’t optional here — it’s expected.

Brian Beglin, Account Manager

Our customers trust us with their reputation. That’s why precision isn’t optional here — it’s expected.

Brian Beglin, Account Manager

Certifications and Expertise

-

3-A Sanitary Standards / USDA / FDA compliance

-

TIG & orbital welding with inert gas purge

-

Polished, bead-blasted, and electropolished finishes (#4–#8)

-

Material traceability and lot documentation

-

CIP/SIP-ready designs for hygienic operations

.png)